Ore Obelisk (Harmony of Minerals)

Artist: Paul Ritter

Year of Work: 1971

Location: North Eastern corner of Stirling Gardens

Medium: Sculpture / Monument / Memorial

Provenance: City of Perth

Just shy of its 50th birthday in July 2021 the Ore Obelisk Artwork in Stirling Gardens was cut into pieces with an oxytorch and put into storage by the City of Perth Council.

This City said at the time, it would explore options for conservation. There has been num public decision or update about its future.

About the Obelisk

It consists of a 15 metre oil drill pipe on which has been threaded fifteen ore samples, representing the main mineral deposits found in Western Australia. From top to bottom the minerals (and where they're from) are;

Dodecahedron (Diamond) Kimberley Region

Magnesite (Magnesium) Ravensthorpe

Manganese Ore (Manganese) Woodie Woodie

Quartz Dolerite (Silver) Kalgoorlie

Cassiterite (Tin) Shaw River

Hematite (Iron) Mt Whaleback

Galena (Lead) Northampton

Supergene (Nickel) Kambalda

Nickel Sulphides (Nickel) Kambalda

Quartz Dolerite (Gold) Kalgoorlie

Spodumene (Lithium) Ravensthorpe

Bauxite (Aluminium) Jarrahdale

Chalcocite (Copper) Ravensthorpe

Jaspilite (Iron) Koolyanobbing

Azurite & Malachite (Copper) Thaduna

Hematite (Iron) Koolyanobbing.

About the artist:

“Paul Ritter (6 April 1925 – 14 June 2010) was a Western Australian architect, town planner, sociologist, artist and author. In his roles as the first city planner of the City of Perth and subsequent two decades spent serving as Councillor for East Perth, Ritter is remembered as a brilliant, eccentric and often controversial public figure who consistently fought to preserve and enhance the character and vitality of the central city district. Today he is primarily remembered for his involvement in preserving many of Perth's heritage buildings at a time of rapid redevelopment and preventing the construction of an eight-lane freeway on the Swan River foreshore.

Ritter was born in Prague on 6 April 1925 to Jewish parents Carl Ritter and Elsa (née Schnabel). In 1939, at the age of 13, Ritter was evacuated from Czechoslovakia to England via the Kindertransport. He graduated as a Bachelor of Architecture and Master of Civic Design from the University of Liverpool. In 1946 he married fellow-graduate Jean Patricia Finch with whom he eventually had five daughters and two sons.

From 1954 to 1964, Paul and Jean Ritter ran the Ritter Press in Nottingham, where Paul taught at the School of Architecture from 1952 to 1964, when the School moved to the University, and a new professor was appointed.

Mr. W. A. McI. Green, Town Clerk of Perth City Council (PCC), invited Ritter to head the council's newly formed Department of Planning. Ritter accepted, and after migrating with his family to Perth in late 1964, began work as Perth's first City Planner in May of the following year.”

Inscription 1:

This ore obelisk is a symbol of the 1960-1970

decade of mineral expansion and was erected to

celebrate the millionth citizen of Western Australia.

The ore obelisk is the successful result of creative experiment in

co-ordinating the co-operative efforts of some fifty public and

private bodies by the Planned Enviroment & Educreational Research

P.E.E.R. Institute , Perth, W.A.

The base is a three dimensional graph and an annual plate is

added each year indicating the relative economic importance from

1960 of the minerals of Western Australia.

Unveiled by the Hon H.E. Graham MLA Deputy Premier.

Minister for Industrial Development & Decentralisation.

27-7-1971

Inscription 2:

Ore Obelisk 1972

Unveiled by the Hon H.E. Graham MLA.,

thanks to Sir thomas Wardle, Lord Mayor

to celebrate the millionth citizen

of Western Australia (1 per sq.mile)

& the harmony of mining & environment.

Design Paul Ritter City Planner.

Planned Environment & Educreation Inst.

co-ordinated 60 donors to the project.

Inscription 3:

Diamond Dodecahedron Addition – 1997

Unveiled by Lord Mayor Dr. P. Nattrass

from dizzy height on cherry picker.

Diamond Symbol Sculpture by

Paul Ritter & Ralph Hibble

Sponsors of the Harmony of Minerals Environmental Competition

Alcoa

Argyle Diamond Mining

BP

Wapet

WMC Resources

Woodside Offshore

Paul Ritter

The Story of the Ore Obelisk

Western Australia's vast mineral development began in earnest about 1964, the year in which the State's now commercial and vital energy reserves of oil and natural gas were discovered at Barrow Island and Dongara.

In the next six years there was a 1,200 per cent increase in mineral production. The vast development projects are directed from Perth, the State's commercial and financial heart, Capital City. The metropolitan population topped the half million.

The rapid economic growth has brought with it explosive building activity in the city centre, which challenged Perth's city planners.

A wedge of land occupied by the Central Railway Station and shunting yards was planned to be developed with underground station open space and mixed accommodation to allow for smooth communication and development to the North. The idea was to erect a centre piece in this proposed complex which would have state, national and international appeal led to the Ore Obelisk.

At this juncture, in 1969, an approach was made to the P.E.E.R. (Planned Environment and Educreation Research) Institute. The Director of the Institute, Paul Ritter, considered something symbolic of the mining boom would be appropriate, and the Ore Obelisk was conceived.

Furthermore, he believed the design would need to reflect future developments and he saw it as a symbol of growth which could, itself, change.

The Ore Obelisk is really a simple mirror symbol Mining goes on underground. To make it visible the process is turned upside down. The steel base is engraved as a 3-D production graph, and each year a current ½ in. plate is laid to keep the graph up to date. From it rises the 45 ft. oil drill pipe. It threads through the 15 ores in turn and at its peak the drill bit dramatically points upwards symbolising the ore boom spirit 'The Sky is the Limit'. The virility of the symbol further reflects the character of the industry. The Obelisk nestles amongst trees and infers that mining need not ruin the environment.

The railway project, which gave birth to the idea of the Ore Obelisk was deferred, but as an exercise in co-ordination and co-operation the P. E.E.R. Institute, donated the design to the community and set about realising it as a creative, social experiment.

The hypothesis was that, given an acceptable idea, co-ordination could make it come true, without a client.

As a first step the Lord Mayor of Perth was shown a scale model and the ideas were explained to him. He kept the model in the Mayor's parlour for some months, to test opinion.

The next approach was to the Minister of Industrial Development and the Premier. Both found the idea attractive but made it clear that the Government would not run the project, but might contribute the ground steel base and the engraving costs if the Obelisk was built.

The private sector was then contacted. Within one week of meeting the President of the Chamber of Mines, the Chamber met, listened, looked, judged and wrote, calling the idea excellent, but declined to undertake the project. But it did offer to obtain, through its members, all the ores required.

Sites had been investigated after official contact with the Perth City Council. The General Purpose Committee was shown a tiny replica of the model, placed on the Selected Stirling Garden site, on Council's special scale city centre model. With a modelscope it was possible to see precisely what the Obelisk would look like when seen from true eye level. Permission to use the site was given unanimously.

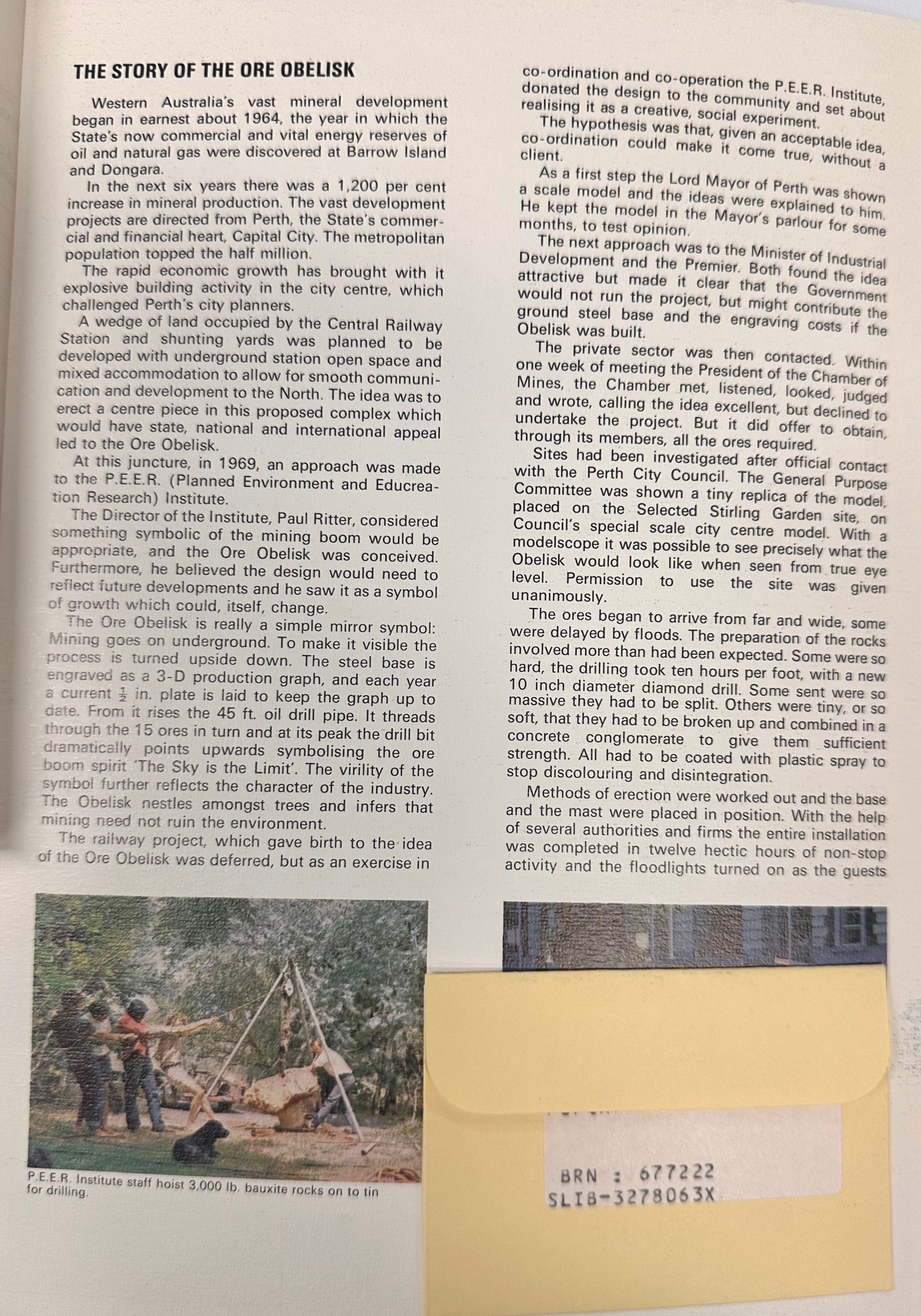

The ores began to arrive from far and wide, some were delayed by floods. The preparation of the rocks involved more than had been expected. Some were so hard, the drilling took ten hours per foot, with a new 10 inch diameter diamond drill. Some sent were so massive they had to be split. Others were tiny, Or so soft, that they had to be broken up and combined in a concrete conglomerate to give them sufficient strength. All had to be coated with plastic spray to stop discolouring and disintegration.

Methods of erection were worked out and the base and the mast were placed in position. With the help of several authorities and firms the entire installation was completed in twelve hectic hours of non-stop activity and the floodlights turned on as the guests walked past to attend the banquet in Government House to celebrate W.A's growth beyond the one millionth citizen.

The Ore Obelisk was unveiled by the Hon. H. E. Graham, M.L.A., Deputy Premier and Minister for Industrial Development and Decentralisation on the 23rd July, 1971. The hypothesis had been confirmed.

There it stands, a stone's throw from the spot where the City was formally founded in 1829, a monument to the energy and good will of the people of Perth.

ACKNOWLEDGEMENTS

The Ore Obelisk was a co-operative effort of some 50 agencies, often solving novel problems.

Mount Newman Mining Co. Pty. Ltd., The Broken Hill Proprietary Co. Ltd., Norseman Gold Mines N.L., Ravensthorpe Copper Mines, British Metal Corporation (Aust.) Pty. Ltd., Western Mining Corporation Ltd., and also Kambalda Nickel Operations, Lake View and Star Limited, North Kalgurli (1912) Limited, all cut attractive lumps of ore and arranged for their transport, in some cases over a thousand miles, and often with the aid of Bell Bros. Pty. Ltd.

Information and help with ores came also from the Minister for Mines and the North-West, the Hon. A. Griffith, and his inspectorate.

West Australian Petroleum Pty. Ltd. (WAPET) donated a high tensile steel oil drill pipe, 45 ft. long, and the entire cost of manufacturing the mast, fixing the collars, and transporting it from Fremantle Foundry and Engineering, who also helped with on-site work.

The steel was weather-proofed by Dimet (W.A.) Pty. Ltd.

The Broken Hill Proprietary Co. Ltd., apart from ore samples, contributed the expensive steel required for the cylindrical base.

Manufacture of the ground steel base, in cooperation with the Government Railway Workshops, was done at cost by Structural Engineering Co. of W.A. Pty. Ltd., with their riggers playing a vital part on erection day.

Mount Newman Mining Co. Pty. Ltd., as well as its ore, provided the costly drill bit for the apex of the Obelisk.

J. O. Clough & Son Pty. Ltd. placed the concrete for the foundations, brought on site by Readymix Concrete (W.A.) Pty. Ltd. with reinforcement supplied by IPA Steel Reinforcement Co.

The mast was transported to the site by Mayne Nickless Ltd. and O'Connor Cranes lifted the mast into place and threaded the 3,000 lb ore lumps onto the mast, a much televised spectacle.

Drilcrete drilled the 10 in. cores, after Ingersoll.

Rand (Aust.) Pty. Ltd. and Atlas Copco Aust. Pty. Ltd. had co-operated to reduce the rocks to the appropriate size.

The P.E.E.R. Institute cast the seven conglomerates with material help from Selleys Chemicals Limited and expert advice from Cretex Construction Limited.

The cut and cast rocks were sprayed by Triplet Industries with material provided by Dulux Colour Centre and compressors from Crommelin's Hire Service.

A crane was provided by the Armadale/ Kelmscott Shire Council for loading the rocks onto a truck kindly provided, with driver, by Kargotich & Orton to transport the rocks to Stirling Gardens.

The Premier Sir David Brand and the Minister for Industrial Development and Decentralisation the Hon. Charles Court, guaranteed the cost of the base.

Graphs, engraving and lettering were done at cost price by W. S. Ball Pty. Ltd., with statistics provided by the Department for Industrial Development.

The Perth City Council contributed the site and the City Engineer, Director of Parks and Gardens, City Building Surveyor, Plant Officer, the Town Clerk each played their part.

The W.A. Fire Brigades Board lent one of their ladders and many firemen were in attendance during erection.

The late Councillor Fletcher donated the floodlights.

The Commissioner of Police provided a guard during the sensitive stages of the first night.

The P.E.E.R. Institute designed, co-ordinated and supervised operations and painted, waterproofed and set the ores into the freshly poured concrete base on erection day.

Bruechle, Gilchrist & Evans acted as honorary structural engineers.

This book was made possible by a donation from Bond Corporation and Goldsworthy Mining Co., and production at cost by Jubilee Printing

WAPET contributed the major photographs.

ORE INFORMATION

HEMATITE (KOOLYANOBBING) ;This specimen of hematite, a variety of iron ore, comes from Mt. Whaleback. Discovery of about 20.000 million tons of high grade iron ore in the north west of the State has resulted in the development of major mines, ports, towns and railways in this area. The ore is shipped to steel plants in Australia, Japan and Europe. Iron ore production in Western Australia will build up to 70 million tons per year by the mid 1970s, with most of this being exported through Dampier and Port Hedland.

AZURITE AND MALACHITE (THADUNA) ;Copper carbonate mined in W.A. as an additive for fertilizer.

IRON ORE (KOOLYANOBBING) ;Iron ore is mined in several areas of the State. The sample shown is from Koolyanobbing where 1:5 million tons per year is mined, then railed to Kwinana where pig iron is manufactured in a blast furnace. The pig iron is exported to Australian and overseas steel plants.

CHALEOCITE (RAVENSTHORPE): These copper ores have been mined at Ravens-thorpe for many years. The ore is processed into copper concentrate for export. The mine has recently ceased production.

BAUXITE (JARRAHDALE): Currently about 3 million tons per year of bauxite are mined at Jarrahdale and railed to Kwinana where it is processed to 1-25 million tons of alumina. The alumina is exported to Victoria and overseas for conversion to aluminium metal. An additional alumina refinery is being constructed at Pinjarra, and others are under investigation at Bunbury, Swan Valley and the Kimberleys.

SPODUMENE (RAVENSTHORPE): Spodumene is an ore of lithium, and is used as an ingredient in ceramics, pottery etc., and in glass manufacture. It is not currently being mined.

GOLD ORE (FIMISTON): The Western Australian gold rush commenced in the 1890s, and the Golden Mile at Kalgoorlie has been the centre of production. Until the 1960s the value of gold produced exceeded all other minerals in Western Australia. The internationally fixed price of gold and rising mining costs have caused a decline in the industry, but 1-7 million tons per year are currently mined for extraction of gold. The gold is refined at the Perth mint.

NICKEL SULPHIDES (KAMBALDA): From Kambalda, where nickel mining first com. menced in Western Australia, The nickel "boom" has arisen from intensive exploration for this valuable mineral and several major deposits have been You in Western Australia. The nickel ore is concentrated at the mine site. Some of the concentrates are shipped overseas via Esperance, While thee seine napr is processed to nickel metal at the Kwinana nickel refinery.

SUPERGENE NICKEL ORE (KAMBALDA): Containing Violarite and Pyrite. See Nickel Sulphides.

GALENA (NORTHAMPTON): Galena is an ore of lead, and has been mined at Northampton for many years. The ore, currently mined at the rate of 500 tons per year is exported via Geraldton.

HEMATITE (MT. WHALEBACK): Very high grade ore up to 65 per cent iron.

CASSITERITE (SHAW RIVER): This ore of tin is mined near Marble Bar and Greenbushes. The ore is concentrated prior to export, and current State production is about 750 tons per year.

QUARTZ DOLERITE SILVER (KALGOORLIE): Silver in Western Australia is recovered as a byproduct of gold and copper mining, and currently about 400,000 fine ounces are produced each year.

MANGANESE (PILBARA): About 200,000 tons of manganese ore per year is produced in Western Australia. Manganese ore is used in the steel industry to confer special properties on steel. The State's production is exported mainly to Japan.

MAGNESITE (RAVENSTHORPE): Magnesite is used in making refractories for the steel industry and as a source of magnesium which is used in light weight alloys. It is not currently mined in Western Australia.

OIL: Western Australia's only commercial oilfield is at Barrow Island, off the north west coast. The oil produced is pumped through submarine pipelines to tankers for delivery to Australian refineries where it is refined to petroleum products (petrol, diesel oil, fuel oil, lube oil, etc.). Production is currently 16 million barrels per year.

(Taken from ‘The Ore Obelisk in Perth’, 1971, Planned Environment and Educreation Research Institute, held in the State Library of Western Australia)